7 Nov

If your ute is your workhorse or weekend escape vehicle, then you know how much your tray needs to bear on daily basis.

Tools tossed in after a long shift. Muddy recovery gear. Pallets that don’t fit. Timber that shifts when you hit a pothole. And let’s not forget the occasional over-load when your friends insist on “just chuck it in, mate, it’ll fit.”

The standard tray body doesn’t love this abuse. It dents, scratches, chips and rusts. And before long, it looks tired & is useless. Because it wasn’t designed for heavy everyday use.

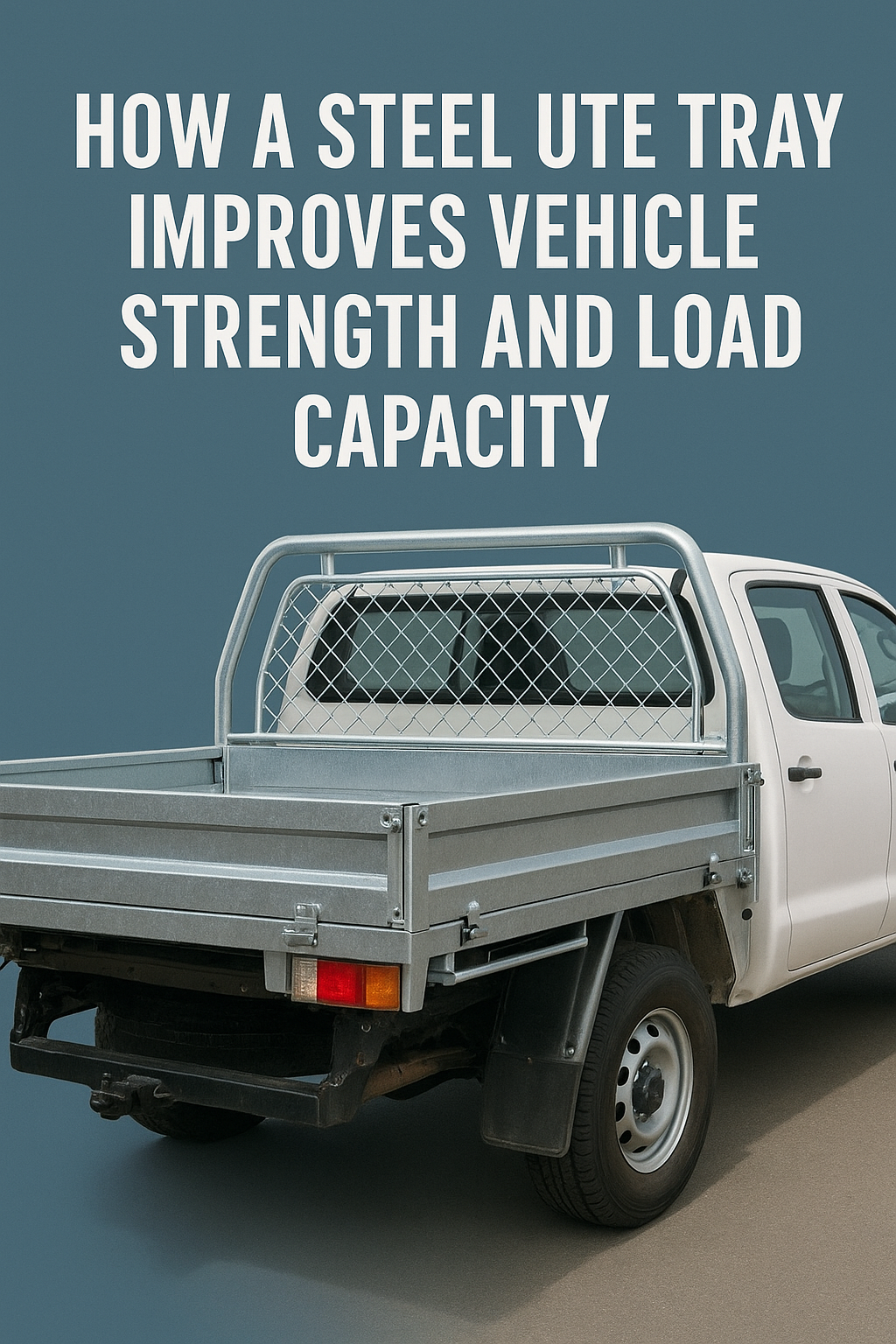

All you need is a durable steel ute tray made for efficiency & long-term performance. It gives your vehicle the strength, load stability, and practicality needed for real-world Aussie work conditions and Perth off-road environments.

Let’s discover the features of heavy duty ute tray with Perth 4WD and learn how it can performance and capability of your ute.

Steel Ute Tray: Strength and Durability for Everyday Use

Steel is chosen in heavy-duty vehicle and transport industries. Because it can handle consistent load pressure, impact, torsional force, and repetitive tough use. In simpler terms, steel holds up when of ute life gets rough.

A heavy duty ute tray made from steel can:

- Support higher payload weights compared to most alloy trays

- Handles dropped tools and machinery without denting easily

- Maintains structural rigidity even through chassis flex off-road

- Performs better under side loads, such as when loads shift on uneven ground

- Provides a more secure mounting surface for racks, canopies and tool boxes

This makes steel particularly valuable in environments that are far from gentle, Means it can cover most work and travel conditions across WA.

Heavy Duty Construction: Secret Behind the Strength of Ute Trays Perth

Modern steel ute trays aren’t just “tough” because they use steel. Ute tray strength and durability comes from reinforced structural design.

A quality high strength steel ute tray includes:

| Component | Role in Load Capacity & Strength |

| Cross-Member Subframe | Distributes weight evenly to reduce stress on the chassis. |

| Box-Section Headboard & Side Rails | Prevents twisting and bending under pressure or when loads shift. |

| Chequer Plate Flooring | Adds rigidity and prevents localised floor denting or flexing. |

| Welded Corner & Edge Bracing | Reinforces high-stress load contact points. |

| Integrated Tie-Down Rings & Rope Rails | Allows safe securing of tools, pallets, machinery and camping setups. |

This is known as a reinforced ute tray design, and it’s essential to avoid the, warping or loosening under heavy use. Even if two trays are both “steel”, the internal frame and cross-member quality will affect how much load they can carry and how long they last.

How to Increase Ute Load Capacity with Steel Trays

Vehicle payload is about how the weight transfers to the chassis and suspension. A high load capacity ute tray made from properly reinforced steel can:

- Maintain a stable load surface (no flexing under weight)

- Allow even securing of gear, preventing movement during travel

- Reduce stress points where cracks or failures typically occur

- Support mounted accessories (e.g., canopies, racks, spare tyres) without reinforcement plates or aftermarket bracing

If you’ve ever noticed an alloy tray “bounce” or flex under heavy weight, that’s a sign of insufficient structural rigidity. Steel trays avoid this problem.

Steel vs Alloy Ute Trays

Many drivers compare steel vs alloy ute trays before upgrading, because the later one comes cheaper. So, let’s compare the features of both, so, you can decide the best.

| Factor | Steel Ute Tray | Alloy Ute Tray |

| Strength & Load Support | Higher load capacity for heavy equipment | Lower load capacity, not suitable for repeated heavy impacts |

| Durability | Resistant to bending, denting and cracking | Can fracture under shock or tool drops |

| Repairability | Easy to weld, straighten and recoat | Repairs require full panel replacement |

| Off-Road Suitability | Handles chassis flex without stress cracks | More prone to fatigue fractures on corrugations |

| Cost | Slightly heavier and may reduce payload on paper | Lighter, may increase official payload |

| Best For | Tradies, farms, mining, full-time load carrying, long-term use | Light-duty use and appearance-focused builds |

Because real-world load capacity matters far more than theoretical payload, tradespeople and regular 4WD owners in WA overwhelmingly choose steel.

Read More at: What’s Better for Your Ute: Alloy or Steel Trays? | Perth 4WD

Steel and WA Conditions: A Perfect Fit

Western Australia has tough weather conditions for every type of vehicle (especially the heavy-duty ones. Utes here are used for:

- Construction sites with rough handling

- Coastal suburbs with salt-laden air (rust risk)

- Mining and agricultural regions with abrasive red dirt

- Remote roads and off-road touring across unpredictable ground

So, a durable ute tray for tradies and touring must withstand:

- High UV exposure

- Dust abrasion on moving joints

- Impacts from gear, tools, and machinery

- Long hours of vibration and chassis flex

Galvanised steel meets all these conditions and that’s why it is a top choice of Perth drivers. Galvanisation adds a protective zinc layer that prevents rust from spreading, and give longer service life. You don’t even have to worry about sensitive parts around weld points and edges where corrosion is most common.

That’s why, we at Perth 4WD, manufacture the trays from predominantly galvanised steel, that can improve durability and lifespan compared to imported or uncoated steel trays.

Custom Fit-Outs: Ute Tray Upgrade for Work Vehicles

WA Tradies need a proper organisation of all your work accessories. Because you can’t spend hours on searching or setting equipment. That’s why we recommend a custom steel ute tray that gives you organised and secure usable space.

Design it just a way you want and enjoy peace of mind later. You can consider the following upgrades to build a custom 4×4 steel tray for heavy loads:

- Under-tray lockable drawer systems

- Side-access tool boxes

- Secure canopy systems

- Water & fuel storage tanks

- Ladder racks and headboard supports

- Tie-down rails and anchor points

- Recovery board and spare wheel mounts

They can even help you in 4WD touring, so, every piece of your gear has a place. For fleet managers, they also mean standardisation and safety compliance.

Why Choose Perth 4WD for Your Steel Tray Upgrade

At Perth 4WD, we design, supply, paint, modify and fit best steel ute trays Australia in-house. Our trays are:

- Made in Perth by Glennic Transport Equipment

- Built from galvanised heavy-duty steel

- Available for all major ute makes and models

- Colour-matched to your vehicle

- Built with reinforced load-bearing structures

- Fitted by experienced technicians

We also supply and fit:

- Paramount tool boxes & steel canopies

- Under-tray drawers

- Water tanks

- Rear racks & custom load systems

If you use your ute for work, farm, business, touring or everyday reliability, we’ll customise it according to your needs.

Need a high strength steel ute tray for your setup?

Get Durable Steel Tray for Ute at Perth 4WD

Upgrading to a steel ute tray is one of the most valuable improvements you can make to your vehicle. It increases strength, improves load capacity, extends vehicle functionality, and stands up to the tough environments of Western Australia.

If your current tray is limiting your work efficiency, storage options, load safety or off-road capability, the solution is simple. Choose a tray that’s built for real use, not just appearance.

Get in Touch with Us to discuss your tray build.